Why T-Technics

- Large range of products

- Gas springs in steel and stainless steel

- Many standardized

- Lots of stock available

- Customized according to customer requirements

- Short delivery time (also with customized products)

- Various brands additionally available

- Mounting parts in steel, stainless steel, plastic, etc.

What is a gas spring?:

A gas spring consists of a cylinder tube with a piston rod moving reciprocally in it, e.g. piston. The gas spring is filled with nitrogen with which the gas spring, depending on the required power and limits of the gas spring itself, can come under (high) pressure. At the front (rod side) the cylinder tube is sealed by means of a guide through which the piston rod moves back and forth. At the rear (house side) the cylinder tube is sealed by means of a bottom piece.

The pressure is the same on both sides of the piston, since there is a throughflow channel in the piston which, by means of a (small) quantity of oil, also ensures an end damping of both the input and the outgoing stroke.

Installation and use:

Gas springs are manufactured from high-quality components and therefore have to be mounted in a certain way as well as being put into use. Think here of characteristics and / or restrictions on materials, temperatures, storage, vibrations, free movement, lateral forces, method of assembly, but of course also the manner of use and / or loading.

For a further / complete explanation of restrictions, see our ”gas spring manual”

In connection with your own safety, it is absolutely forbidden to make changes to gas springs by drilling, sawing or welding.

Additionally and explicitly stated here that gas springs should never (directly) be cleaned with a steam cleaner or high-pressure sprayer.

Feel free to ask our advice for deviating installation or other questions..

Once you have ordered and / or filled your gas springs, can not be exchanged or be returned..

Performance and specifications:

The T-Technics gas push- and gas pull springs as well as special products are tailor-made for you in-house. With larger numbers, the gas springs can be provided with your own name and article number

The oil contained in a gas spring ensures the final damping of both the ingoing and the outgoing stroke. This damping can be increased by us if desired for filling and even reduced in certain types.

All gas springs are refillable, that is to say that the extension force can be increased later by T-Technics. However, versions are also available with a panel, which means that the extension force can also be lowered later on.

T-Technics can also perform certain types of gas springs with a device that allows you to relieve the pressure yourself. I.e. T-Technics fills the gas springs at the maximum pressure (depending on type). You can then mount the gas spring “in the work” and then release the pressure until the system is working properly. See the gas spring type “Controlspring” (this is the link to the pdf-file).

Because the gas springs at T-Technics are filled “in the house”, every desired extension force F1 can be ordered. This, of course, within the limits of the type of gas spring. With this, longer delivery times are somewhat avoided. The extension force F1 of the gas spring is determined by multiplying the filling pressure with the surface of the piston rod.

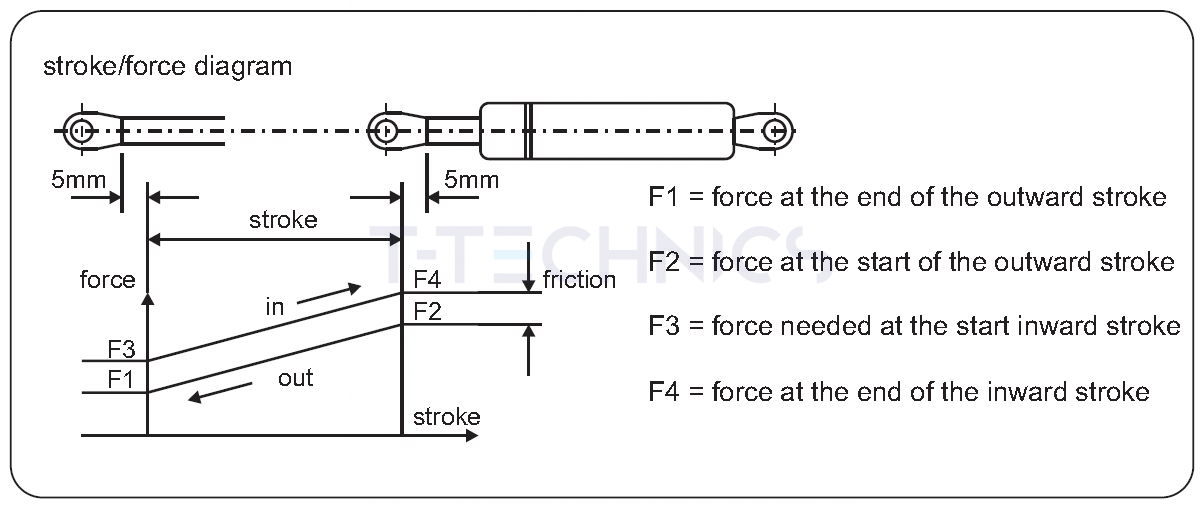

The extension force F1 is measured by pressing the rod 10 mm and returning it again 5 mm and is expressed in Newton (N). See the table below.

T-Technics gas springs:

The T-Technics gas springs, manufactured in-house, are offered in a steel version and in a stainless steel version. The materials used / to be applied here are further specified in our ”gas springs manual”

Progressiveness:

T-Technics gas springs:

Because T-Technics has its own production facility for gas springs, T-Technics can change the combination piston rod / cylinder tube, in principle realize any combination. T-Technics can further inform you about this. The resulting pressure increase in the gas spring, when using the entire stroke length, as a result of operating it, is called “progressiviness”. This varies per type of gas spring, namely:

Progressiviness gas push springs:

|

4/12 = F1 + 19%

|

10/28 = F1 + 21% | 14/40-42 = F1 + 17% | 30/60 = F1 + 40% |

| 6/15 = F1 + 27% | 12/25 = F1 + 42% | 20/35 = F1 + 80% | 30/65 = F1 + 33% |

| 8/19 = F1 + 33% | 14/28 = F1 + 52% | 20/40-42 = F1 + 45% | 40/100 = F1 + 25% |

| 10/23 = F1 + 33% | 14/35 = F1 + 28% | 20/45 = F1 + 33% |

Progressiviness gas pull springs:

|

6/19 = F1+ 33%

|

8/23 = F1 + 36%

|

10/28 = F1 + 36%

|

14/40-42 = F1 + 42%

|

Airax-gas springs:

The Airax gas springs are supplied as standard with a black coated or sprayed cylinder housing, resulting in excellent corrosion resistance. The occurring pressure increase in the Airax gas spring due to its operation is called “progressivity”. This varies per type of gas spring, namely::

Progressiviness gas push springs:

|

6/15 = F1 +27%

|

8/20 = F1 + 25%

|

10/22 = F1 + 33%

|

14/28 = F1 + 45%

|

Tolerances on the pressure:

The tolerances in pressure apply to T-Technics and Airax gas springs. The gas spring can be filled at customer’s request with the desired pressure, but naturally within and below the specific gas spring. At the pressure (F1) with which the gas spring is filled there is a certain tolerance, namely:

| F1 = 20N – 50N, tol. = +/-10N | F1 = 250N – 750N, tol. = +/-30N | F1 = 1500N – 2500N, tol. = +/-100N |

| F1 = 50N – 250N, tol. = +/-20N | F1 = 750N – 1500N, tol. = +/-50N | F1 = 2500N en meer, tol. = +/-250N |

Tolerances on the length:

The tolerances on the length measurements apply to T-Technics and Airax gas springs. The tolerances on lengths are +/- 2 mm.

Inventory management:

For further explanation of the stocking of our gas springs, see our ”gas springs manual”

Warranty terms:

For further explanation of the warranty period, see our ”gas springs manual”

Environment:

For further explanation of our gas springs and the environment, see our ”gas springs manual”

Shredding:

For further explanation of the scorching of our gas springs, see our “gas springs manual”

Changes:

We reserve the right to changes in material types / choices as well as versions.